Automatic system for dosing liquids chemicals and auxiliaries.

The operation of our systems for the volumetric dosing of auxiliaries and chemicals is very simple, fast and precise.

consists of a suitably sized storage and a control system between the dosing pump and the flow meter.

The flow rate and accuracy are dictated by the sizing of the latter.

The process takes place completely automatically. Starting from the receipt of a single or multi-component recipe.

Sequentially, the quantity of product to be dosed, once mathematically transformed into parts of a litre, will be aspirated by a pump from its container and sent through a volumetric counter to the chosen destination. The control software will also check for any incompatibilities between products and eventually place a water buffer between them. Iterations between hosts and dyeing machines, process status and consumption reports are always available.

At the end of the dosage, the whole system can be washed by sending the residual part to the point of use or / and rinsed.

All parameters for dosing, for sending and for washing and rinsing can always be set by the user even during the various processes.

A loading unit supplies the storage.

We have many way to refill the tanks. the simple and cheapest one is to use, where it is possible, one single pump for all products. Another way is to use more then one pumps to increase speed and/or to separate incompatible products. all units are provided with security device for loading and picking chemicals.

The storage can be customized in sizing. The tanks can be positioned on a mezzanine or simply rest to the ground.

To prevent environment leak and to preserve the safety of the workers, chemicals tanks are normally safety bund.

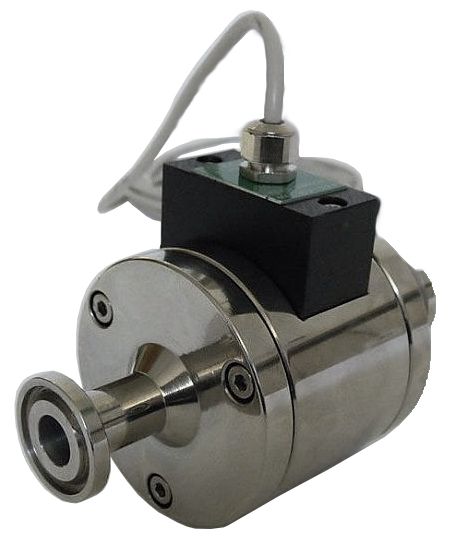

The flow meters can be of different types depending on the accuracy and type of products to be dosed.

You can have mechanical, magnetic or mass flow meters.